Jewelry casting is a time-honored process that combines artistry and precision to create intricate and durable pieces. By using advanced techniques and high-quality materials, jewelers can produce detailed designs that meet the demands of modern consumers. The evolution of casting methods, such as lost-wax casting and 3D printing, has expanded the creative possibilities, allowing for greater customization and innovation. Ultimately, jewelry casting remains a vital part of the industry, ensuring that each piece is both beautiful and enduring.

For 3D part, we have LCD,DLP and white wax 3D printer.

For Molding, we have vulcanizer and pneumatic vulcanizer

For Wax injector, we have IW5 IW5S IW6 IWPRO IWPlus

For Mixing, we have 1 flask mixer, 3 flask mixer, 5 flask mixer, 6 flask mixer and 10 flask mixer. Supporting customized bigger size

For Burnout oven, we have from 2-60Pcs flask standard size, support customized bigger. Also 17pcs rotary oven and 40pcs rotary oven

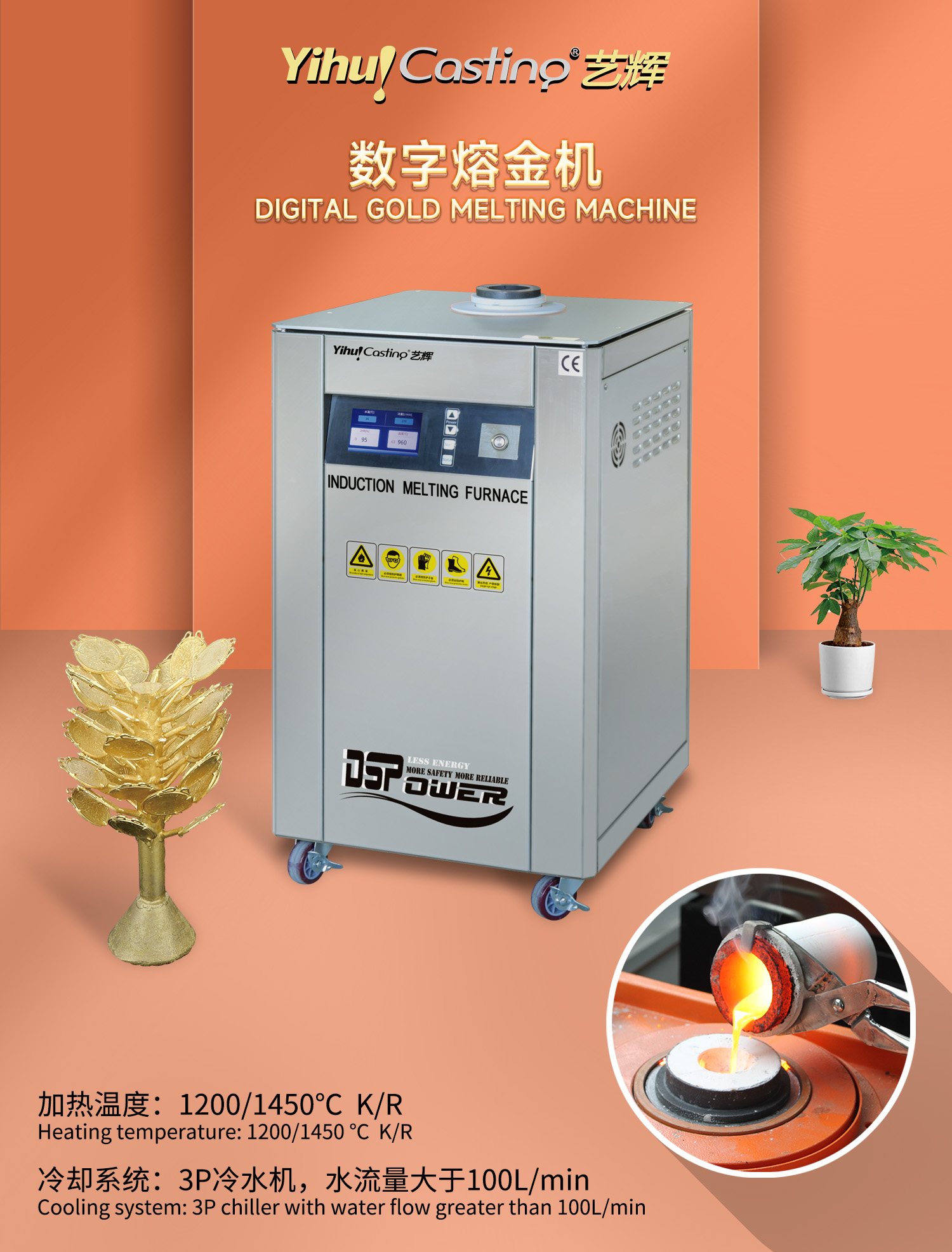

For Melting, we have electrical melting furnace from 1-5kg, Mini DSP furnace 2kg, Mini induction furnace 1-2kg, DSP melting furnace 1-10kg, Induction melting furnace 1-10kg, platinum melting furnace 1-4kg, tilting type melting furnace 12kg 20kg and 40kg

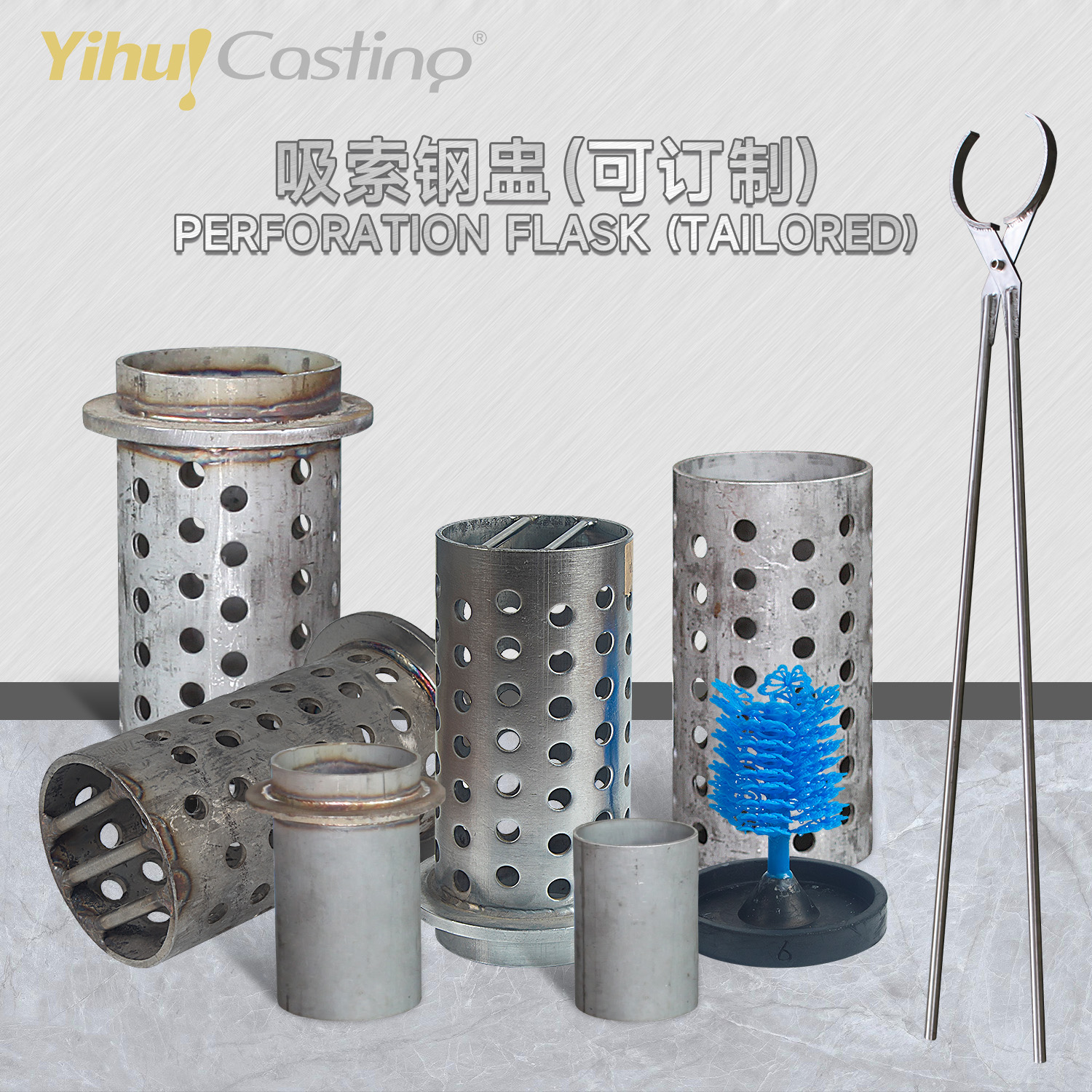

For casting, we have SVC casting machine,AVC-III casting machine,DVC-II casting machine,DVC-III casting machine, RC150 centrifuge casting machine,CC150,CC350 and CC1000 centrifuge casting machine. 3kg, 5kg,8kg and 30kg continuous casting machine. 1kg and 4kg gold bar making machine.

Starting from design to final producuts, Yihui Casting Technology offers comprehensive jewelry casting solutions, ensuring high precision and quality in every piece. Our expertise in advanced casting techniques guarantees exceptional results for all your jewelry needs.

online service

online serviceScan to wechat :