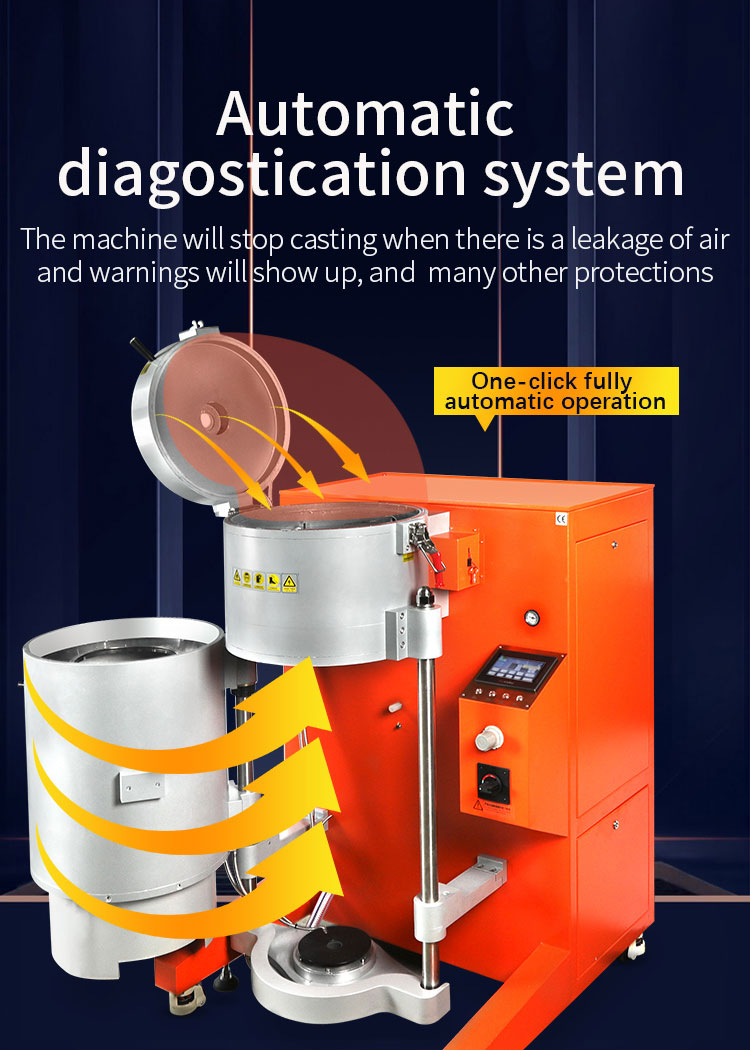

Z.M.CM.DVC-30 is a vacuum pressure casting machine with completely open program, users can freely program to meet various processes and multi-functions, it is suitable for superalloy casting, the temperature control is accurate ± 3 'C the measured loss is small and the casting pieces are of high quality. Automatic diagnosis system, high reliability of the casting system, such as vacuum leakage of the flask, no casting and automatic reminder and many other protections.

Product Basic Information:

Product Name: Z.M.CM.DVC-30 Vacuum Pressure Casting Machine

Main Keywords: Vacuum Pressure Casting Machine, Completely Open Program, Superalloy Casting

Attribute Keywords: High Temperature Control Accuracy, Small Measured Loss, High-Quality Casting Pieces, Automatic Diagnosis System, High Reliability, Multiple Protections

Product Features & Advantages:

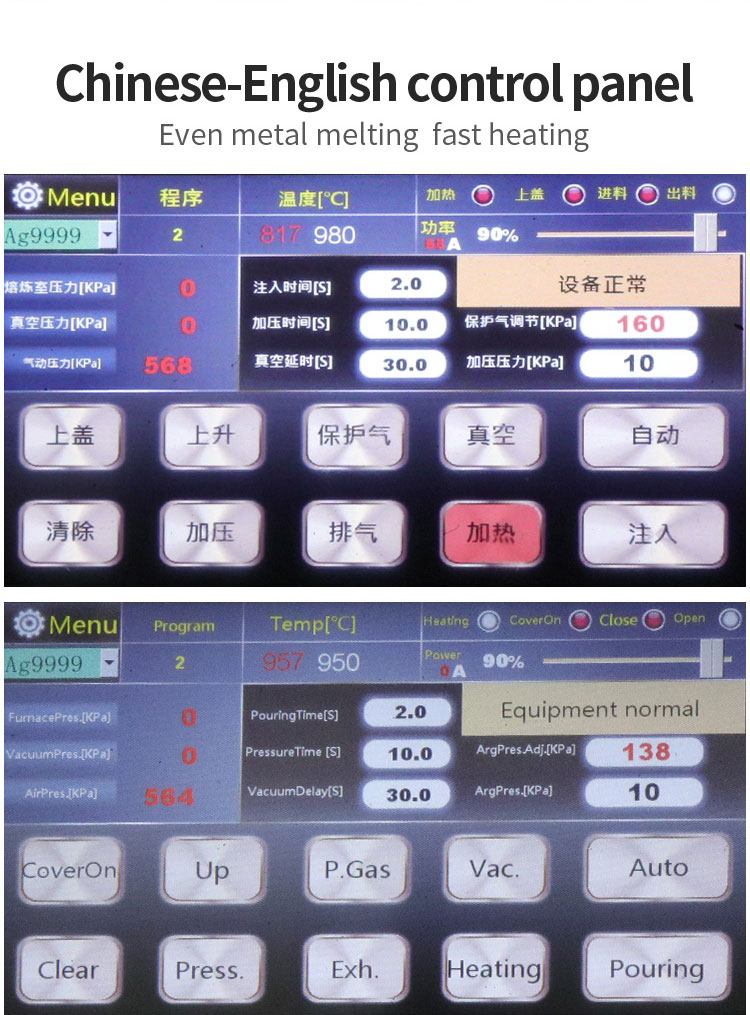

Flexible Programming: Allows users to freely program to meet diverse processes and multi-functional requirements.

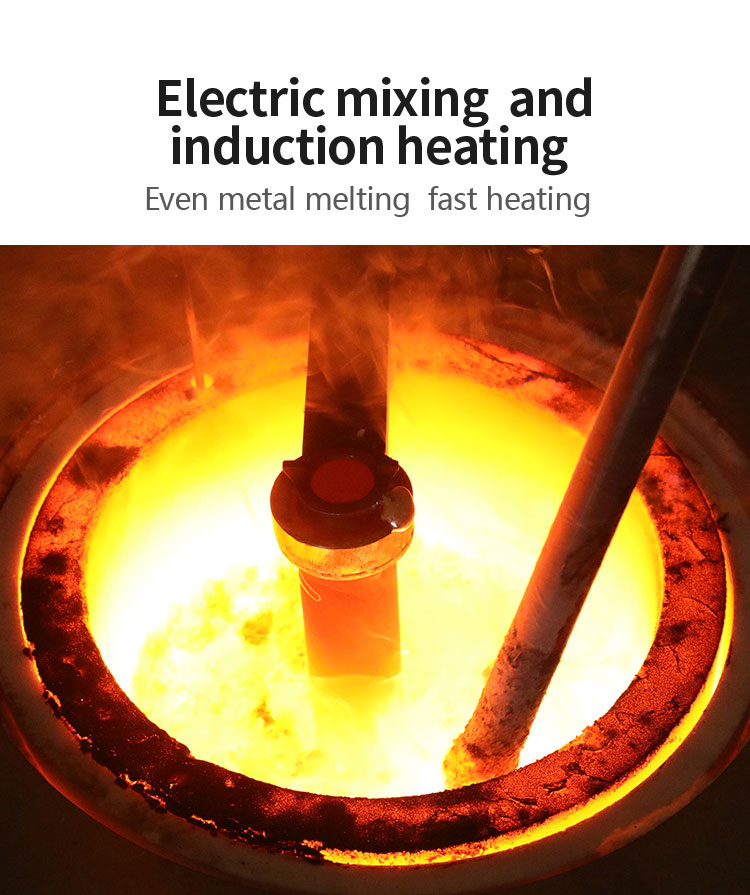

Superalloy Casting Capability: Specially suited for casting superalloys, ensuring precision and quality.

Accurate Temperature Control: ±3°C accuracy ensures stable and consistent casting temperatures.

Low Measured Loss: Reduces material waste and improves overall efficiency.

High-Quality Casting Pieces: Produces castings of exceptional quality.

Automatic Diagnosis System: Enhances machine reliability and maintenance efficiency.

High Reliability: Features multiple protections, including vacuum leak detection, no casting reminder, and more.

Target Audience:

Manufacturing industries involved in metal casting, particularly those requiring high-precision casting of superalloys.

Engineering and research organizations conducting advanced material research and development.

Foundries and casting shops seeking to improve casting quality and efficiency.

SEO Extra Requirements:

Keyword Optimization: Ensure that the website content and meta tags are optimized for the main and attribute keywords mentioned above.

Unique and Informative Content: Create original and detailed product descriptions, specifications, and application examples to improve search engine rankings.

Backlinks and Internal Linking: Build quality backlinks from relevant websites and ensure internal linking within the website to strengthen the SEO foundation.

Image Optimization: Optimize product images with appropriate alt tags and filenames containing keywords.

Mobile-Friendliness: Ensure the website is fully responsive and mobile-friendly to cater to a wider audience.

Regular Content Updates: Publish informative blog posts, case studies, and news updates related to vacuum pressure casting and superalloys to attract and retain visitors.

Structured Data Markup: Use schema.org markup to enhance the visibility of product information in search engine results pages.

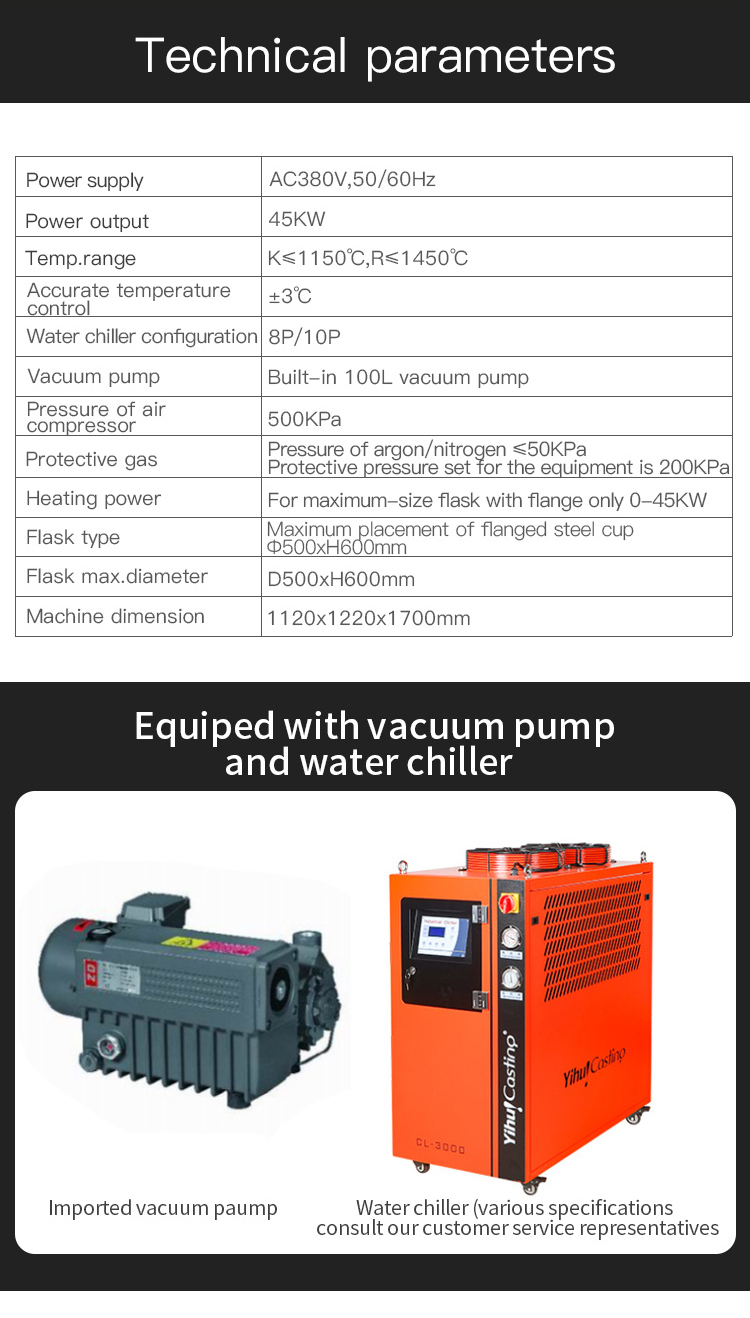

| Model | Z.M.CM.D30 |

| Power supply | AC380V,50/60Hz,3 phase, 45KW |

| Temperature range | 0-1150℃ (K type) 0-1450℃(R type) |

| Temperature control accuracy | ±3℃ |

| Chiller | 8P/10P |

| Vacuum pump | Built-in 100L |

| Air compressor pressure | 500KPa |

| Heating power | 0-45KW Automatic allocation |

| Flask size | D500×H600mm |

| Protective gas | Argon/nitrogen, system parameter setting pressure≤50KPA, equipment input protective gas pressure 200kpa |

| Body size | 1120×1220×1700mm |

online service

online serviceScan to wechat :