Introducing our state-of-the-art Centrifugal Casting Machine, engineered with a revolutionary Unique Dual Swing Arms design that significantly enhances centrifugal force, ensuring impeccable casting results. Powered by a high-performance servo motor, this machine delivers unparalleled rotation acceleration and centrifugality, making it the go-to choice for precision casting of Platinum (PT), as well as smaller batches of K-gold and silver.

With its advanced technology and robust construction, our centrifugal casting machine is designed for jewelers, metalsmiths, and industrial casting applications alike. The enhanced centrifugal force achieved through the dual swing arms ensures superior material distribution and a flawless finish, particularly when working with delicate and high-value metals like Platinum (PT).

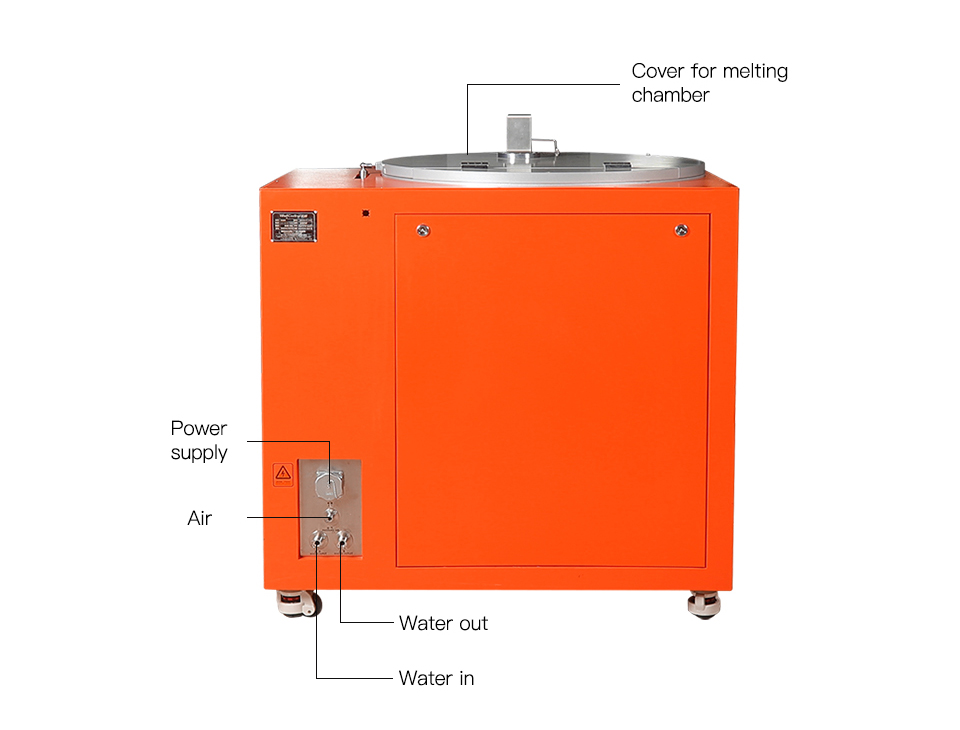

| Model | Z.M.CM.CC350 |

Power supply | Single phase 220V50HZ single phase current 30A |

Temperature range | 800-2000°C |

Pliers specifications | 350A-1 quartz melting gold cup |

Pliers model | C.CP0350A-1 |

Steel size | 90x100mm |

Casting method | High speed vacuum centrifugal rotatior |

Speed | Adjustable,up to 1000 rev / min |

Cooling method | water cooling |

Vacuum device | Built-in |

Body size | 830x1080x080mm |

Weight | 450KG |

Key Features:

1.Unique Dual Swing Arms: Amplifies centrifugal force for superior casting quality.

2.High-Performance Servo Motor: Delivers rapid rotation acceleration and precise control.

3.Versatile Casting Capabilities: Ideal for Platinum (PT), K-gold, and silver casting.

4.Precision Engineering: Ensures accuracy and repeatability for every casting job.

online service

online serviceScan to wechat :