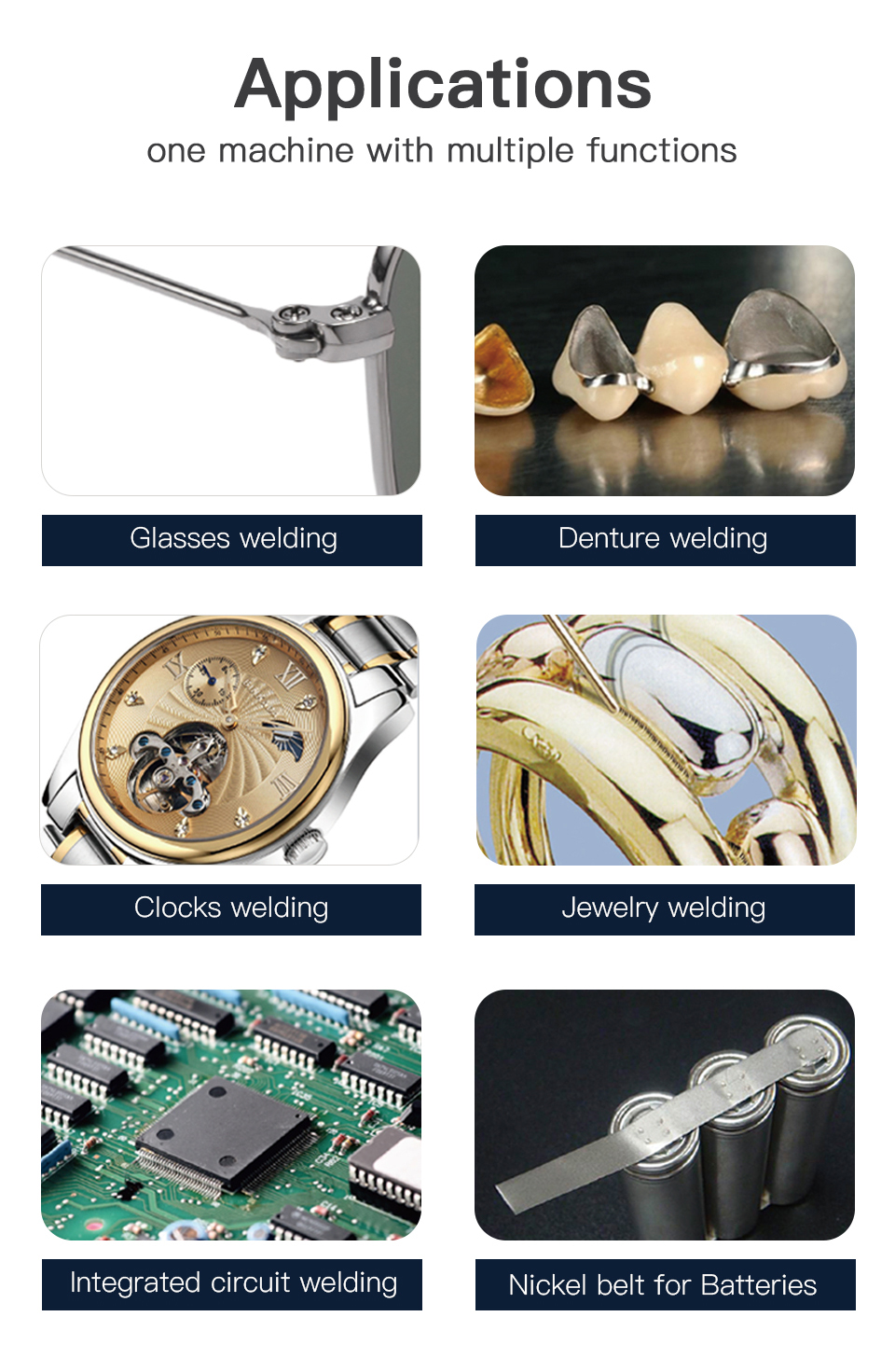

Applied to fill holes of gold and silver jewelry, trachomaspot welding, seam lines and repair parts inlaid claw feet andother parts of the welding.It can also be used to makedentures and trachoma welding small precision parts suchas batteries nickel belt, lC lead, watches gossamer, picturetube, an electron gun assembly, and other fields. Small heataffected zone during welding; welding spot size can be adjusted;solder fine, smooth, beautiful, without too much after thewelding process; accurate positioning; welding speed, highquality, pollution-free solder, efficient and environmentallyfriendly. Application: Kinds of metals. Such as: gold, silver,platinum, stainless steel, titanium and its alloys.1.A key operation: a key switch, simplify the start-upprocess equipment,convenient for the operator to thetedious process.

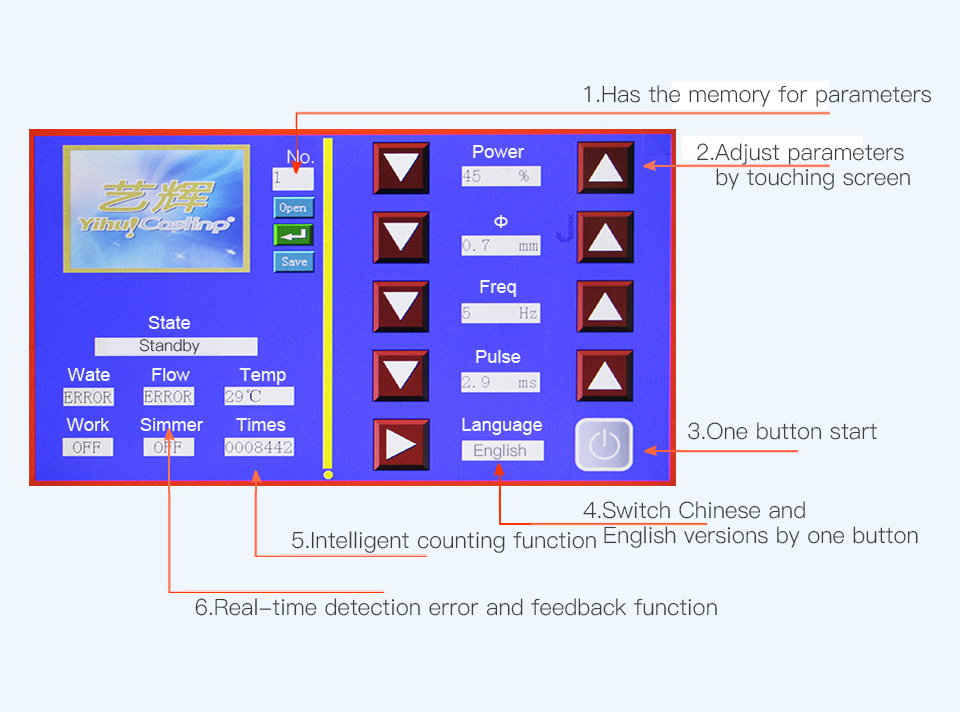

2.MCU control: can store 50 groups used weldingparameters,convenient use again.3.Small volume and light weight: reduce the workspace, easy to transport and move.

| Model | M.SW.DKLW200 | M.SW.DKLW300 |

| Power supply | 220V/50Hz/20A | 220V/50Hz/30A |

| Maximum peak power | ≤4.5KW | ≤7KW |

| Average Pulse Energy | ≤200W | ≤300W |

| Wave length | 1064nm | 1064nm |

| Pulse Frequency | 0-20Hz | 0-20Hz |

| Pulse Length | 0.1-5.0ms | 0.1-10.0ms |

| Spot diameter | 0.1-2.0mm | 0.1-2.0mm |

| Observation rate | 10 times | 10 times |

| Working distance | 90 mm | 90 mm |

| Using condition | Clean,no dust and vibrate,Temp13 ℃-28℃,Humidity 5%-75% | Clean,no dust and vibrate,Temp13 ℃-28℃,Humidity 5%-75% |

| Dimension(Main) | 840x450x500mm | 840x450x500mm |

| Chiller's size | / | 610x370x620mm |

| Machine's net weight | 60kg | 60kg |

| Chiller's net weight | / | 46kg |

Precision Welding Capability: Designed for intricate jewelry repairs and small precision parts, ensuring precise, smooth, and visually appealing welds.

Versatile Application: Suitable for filling holes, trachoma welding, seam repairs, inlaid claw feet, and other jewelry parts, as well as welding small precision components like battery nickel strips, IC leads, watch hairsprings, CRT tubes, and electron gun assemblies.

Minimal Heat Impact: Small heat-affected zone during welding, preserving the integrity and aesthetics of delicate materials.

Adjustable Spot Size: Flexibility to adjust welding spot size according to different applications and requirements.

Efficient & Eco-Friendly: High welding speed, pollution-free welds, and energy efficiency make it an environmentally friendly solution.

User-Friendly Design: One-key operation simplifies the startup process, while MCU control allows storing 50 sets of welding parameters for convenient reuse.

Compact & Portable: Lightweight and space-saving design, ideal for limited workspaces and easy transportation.

online service

online serviceScan to wechat :