The LS-32 Vertical Centrifugal Grinding Machine enhances efficiency by 10-15 times with its planetary transmission mode, ideal for small-batch workpiece grinding and polishing. Perfect for aluminum and zinc die castings, clock parts, locks, electronics, and jewelry, it offers smooth operation, low noise, and long life due to its synchronous belt transmission. Featuring imported polyurethane glue, an electronic brake system, and adjustable speed control, the LS-32 ensures safe and optimized processing. Its four removable drums allow easy cleaning and versatile handling of multiple workpieces simultaneously.

The LS-32 Vertical Centrifugal Grinding Machine enhances efficiency by 10-15 times with its planetary transmission mode, ideal for small-batch workpiece grinding and polishing. Perfect for aluminum and zinc die castings, clock parts, locks, electronics, and jewelry, it offers smooth operation, low noise, and long life due to its synchronous belt transmission. Featuring imported polyurethane glue, an electronic brake system, and adjustable speed control, the LS-32 ensures safe and optimized processing. Its four removable drums allow easy cleaning and versatile handling of multiple workpieces simultaneously.

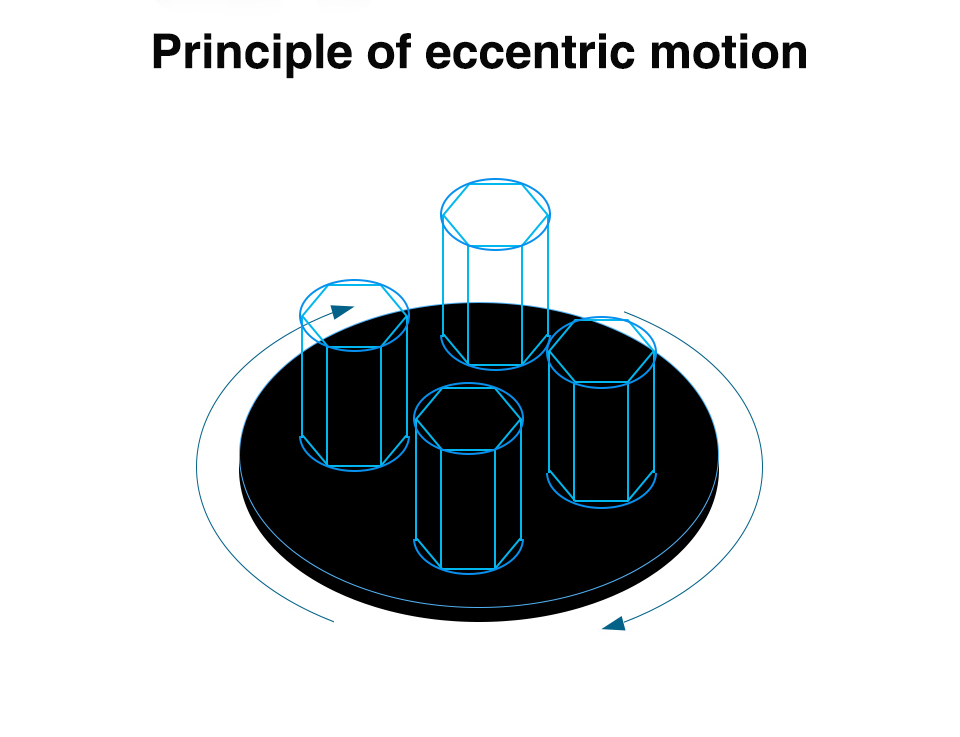

Key Features & Advantages: Designed with planetary transmission and a centrifugal motion principle, this machine achieves grinding efficiency levels 10-15 times higher than conventional drums. It's equipped with synchronous belt transmission for smooth, quiet operation, making it suitable for environments where noise reduction is critical. The inner barrel features polyurethane glue, providing durability, acid and alkali resistance, and wear resistance, ensuring prolonged lifespan and reliable performance.

Key Features & Advantages: Designed with planetary transmission and a centrifugal motion principle, this machine achieves grinding efficiency levels 10-15 times higher than conventional drums. It's equipped with synchronous belt transmission for smooth, quiet operation, making it suitable for environments where noise reduction is critical. The inner barrel features polyurethane glue, providing durability, acid and alkali resistance, and wear resistance, ensuring prolonged lifespan and reliable performance.

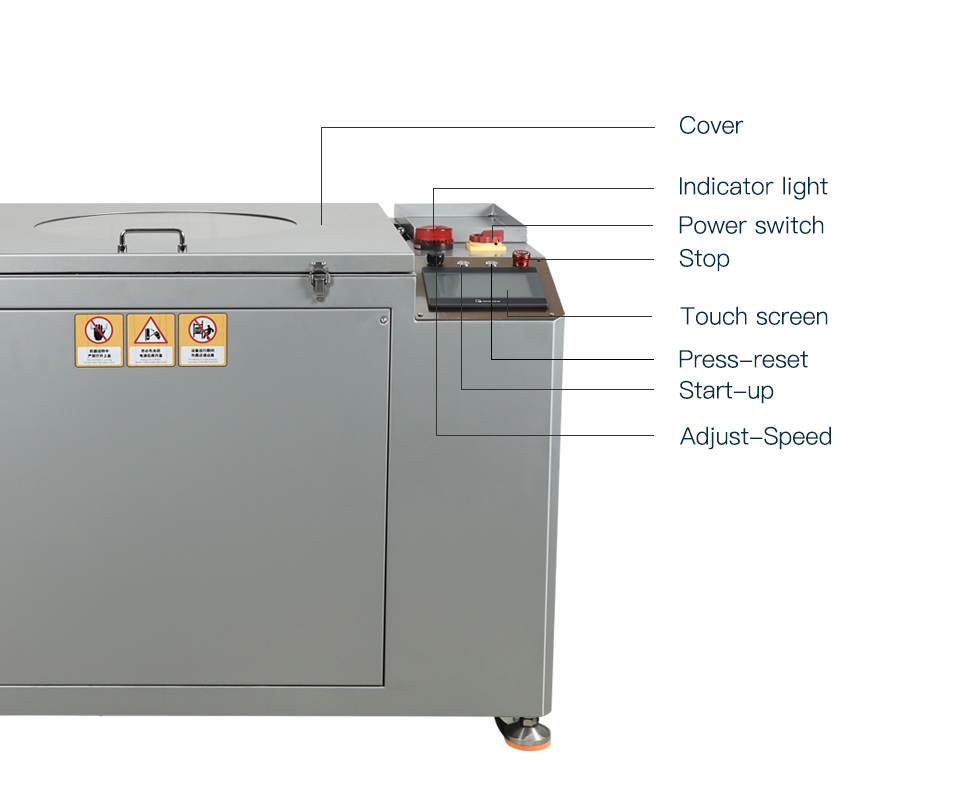

Safety & Precision: For enhanced safety and precision, the LS-32 includes an electronic brake system and frequency control for adjustable speed settings. This allows real-time speed adjustments to minimize defects and optimize results, maintaining high standards of accuracy in processing various workpieces simultaneously.

Easy Maintenance & Multi-Functionality: With four removable drums, the machine facilitates easy cleaning and the ability to process multiple workpieces or different types separately. It's ideal for small batch workpieces such as aluminum and zinc die castings, clock parts, locks, electronic accessories, and intricate jewelry pieces requiring meticulous surface finishing.

| capacity | 4*4L |

| Voltage | 220v 50/60hz |

| power | 1.5kw |

| machine size(mm) | 1120*880*912 |

| weight(kg) | 365 |

Target Customers: This machine caters to jewelry manufacturers seeking high-precision polishing solutions, metalworking industries processing aluminum and zinc die castings, and precision engineering sectors focusing on small batch workpieces. Research and development labs benefit from its versatility in surface modification and preparation for further treatments.

online service

online serviceScan to wechat :