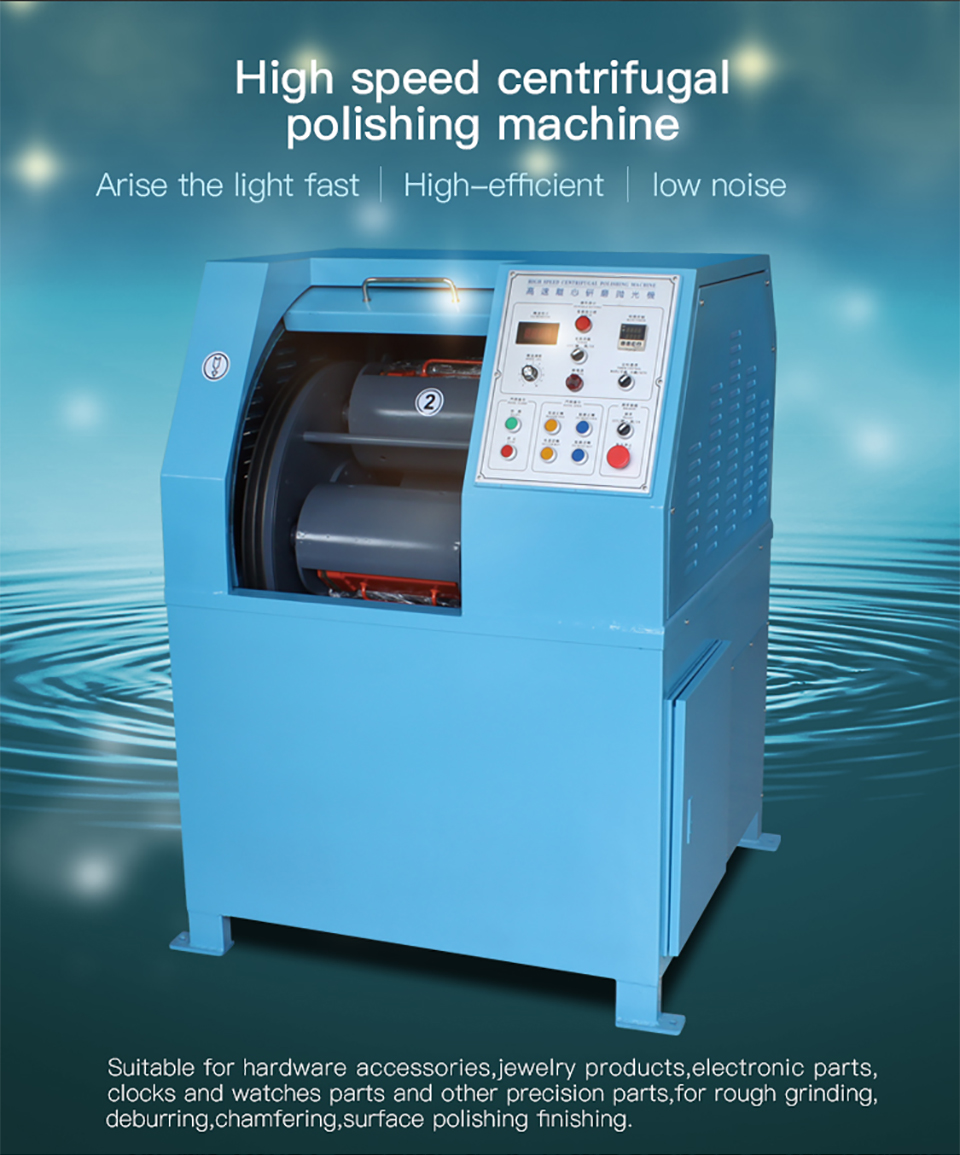

This high-speed centrifugal polishing machine is designed for efficient and low-noise polishing of hardware accessories, jewelry products, and other precision parts. It offers adjustable grinding speed, reliable operation, and easy maintenance with no need for additional auxiliary equipment.

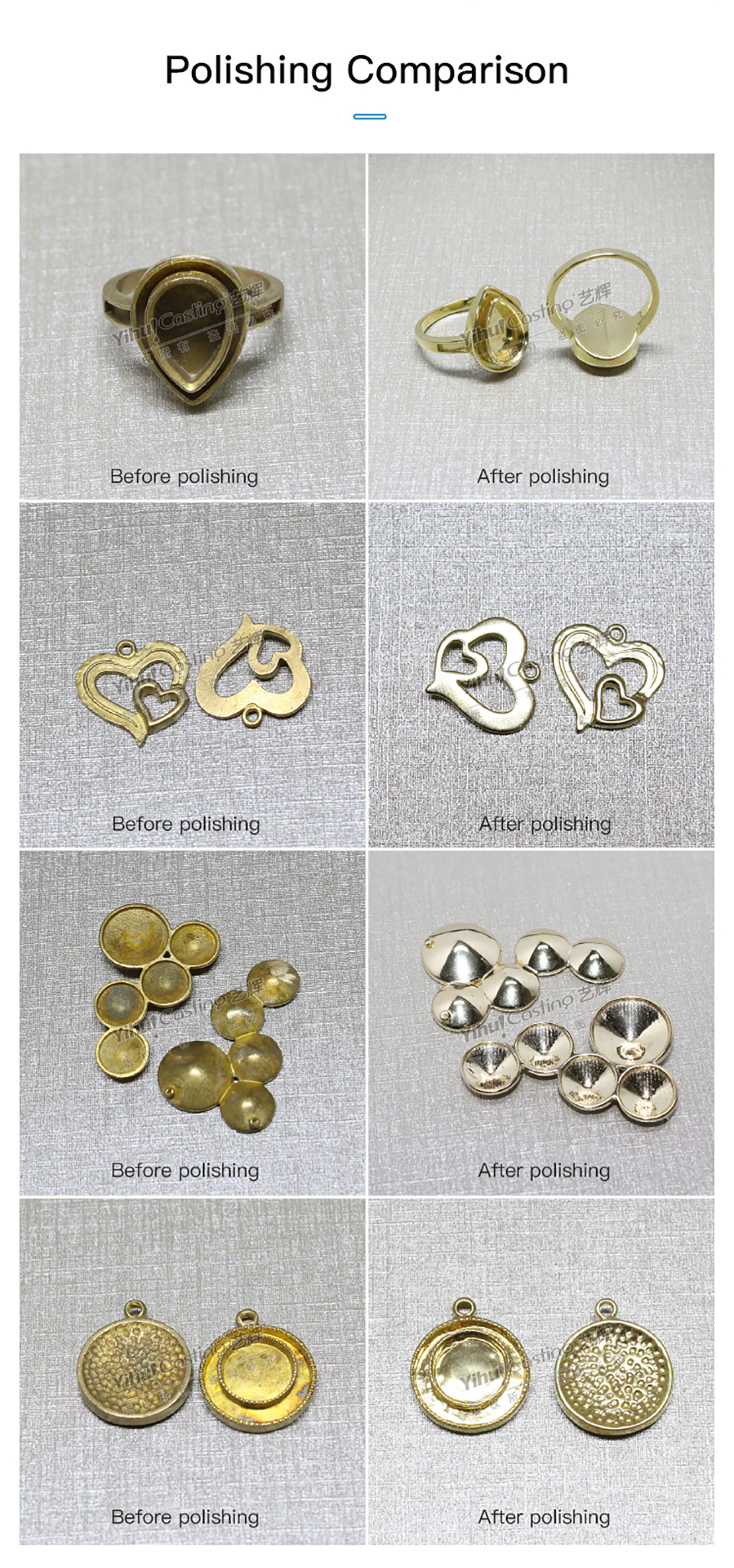

The high-speed centrifugal polishing machine is ideal for hardware accessories, jewelry products, electronic parts, and precision components like clock and watch parts. It’s engineered for rough grinding, deburring, chamfering, and surface polishing. With features like adjustable grinding speeds, imported V-belt drive for stable operation, and an easy-to-use control panel, this machine is perfect for achieving high-quality finishes. Its planetary rotation and frequency conversion speed regulation ensure a powerful grinding force, making it suitable for materials like gold, silver, copper, stainless steel, and alloys. Please note that plastic abrasive stones and grinding liquid are required for optimal performance and should be purchased separately.

The High-Speed Centrifugal Polishing Machine is a robust and efficient solution for polishing and finishing various precision parts, including hardware accessories, jewelry, electronic components, and clock and watch parts. Designed to deliver high-quality results, this machine combines speed, precision, and ease of use to meet the demands of modern manufacturing.

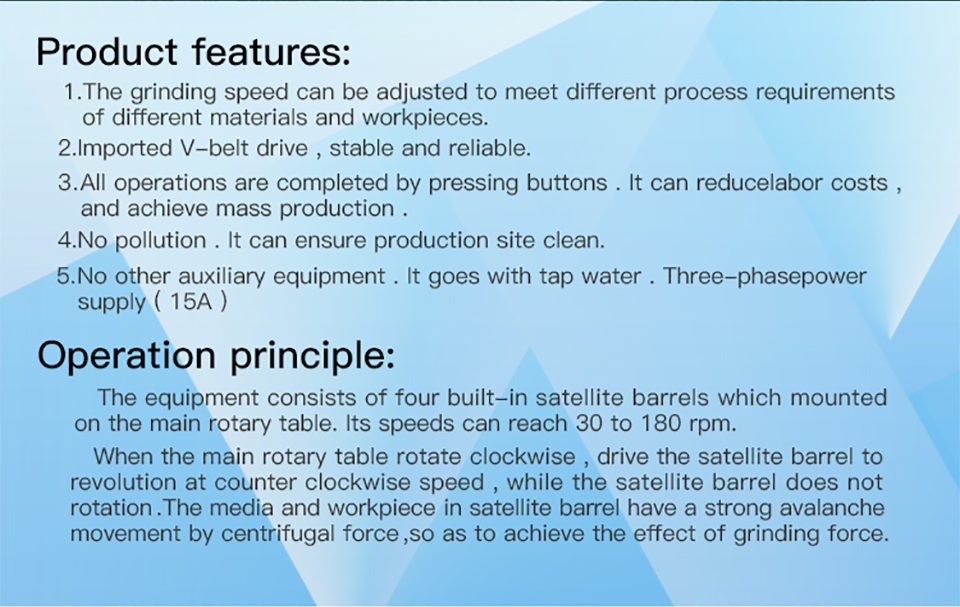

Key Features:

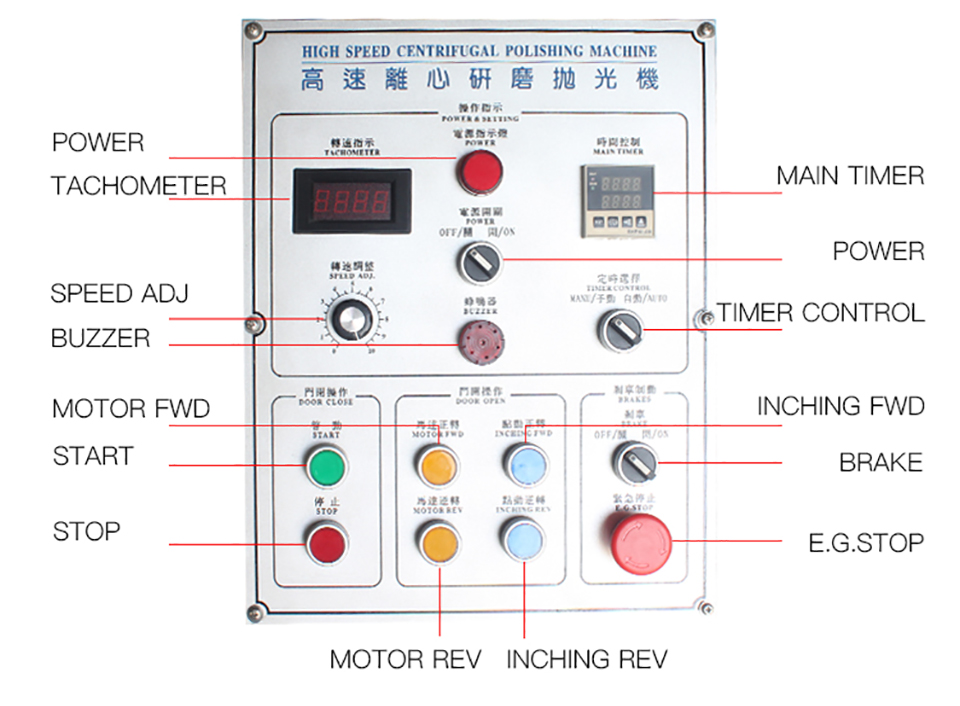

1. Adjustable Grinding Speed: The grinding speed can be easily adjusted to suit different materials and processing requirements, providing flexibility and control over the finishing process. Whether you’re working with delicate jewelry pieces or more robust hardware, the machine adapts to your needs.

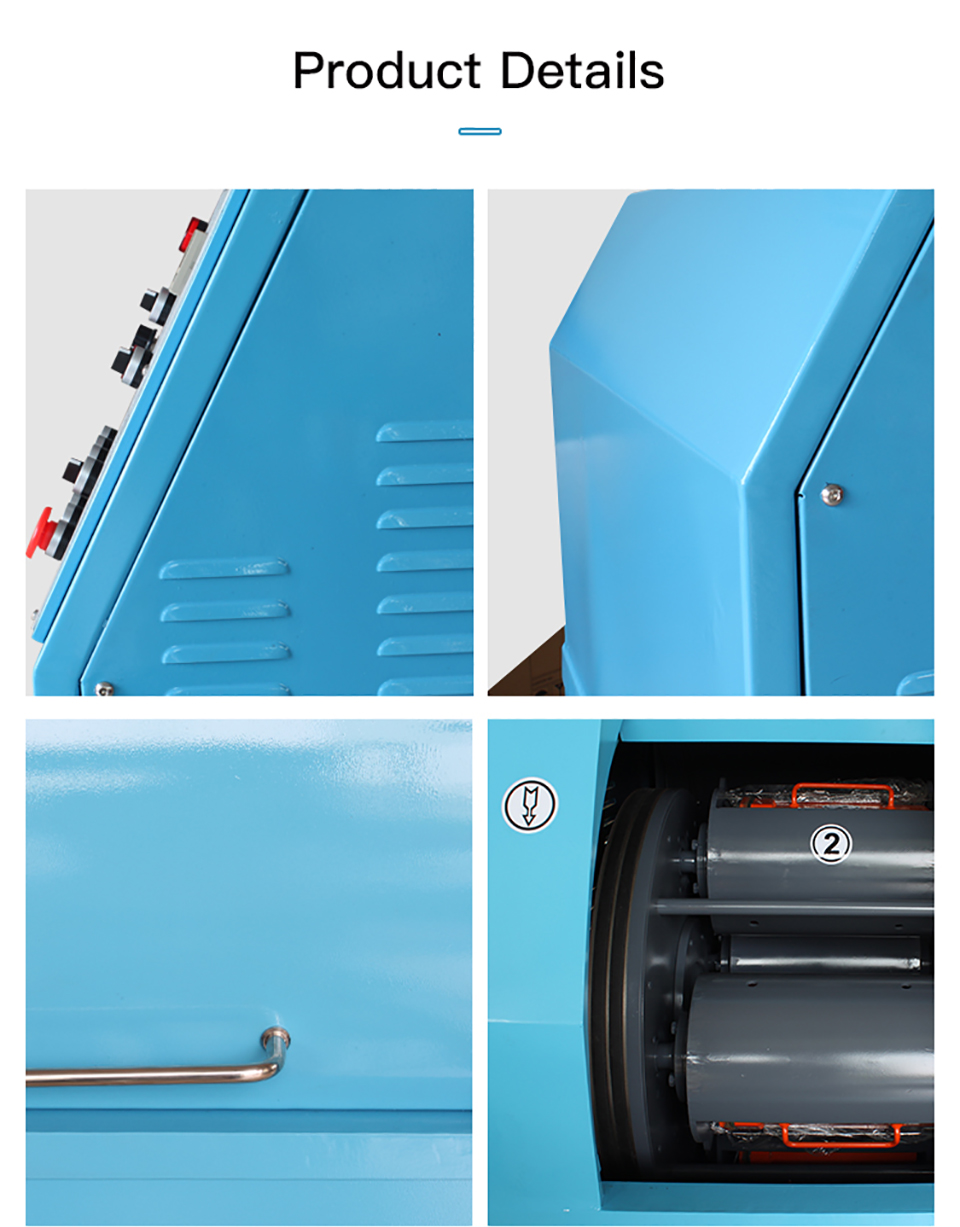

2. Imported V-Belt Drive: The machine is equipped with an imported V-belt drive, ensuring stable and reliable operation. This feature minimizes the risk of mechanical failure and prolongs the machine’s lifespan, offering consistent performance over time.

3. User-Friendly Operation: All operations are completed with the press of a button, significantly reducing labor costs and enabling mass production. The machine’s intuitive interface allows for quick setup and operation, even for those with limited technical experience.

4. Environmentally Friendly: The machine operates with tap water and does not produce any pollution, ensuring a clean and safe production environment. Its design eliminates the need for additional auxiliary equipment, simplifying the polishing process.

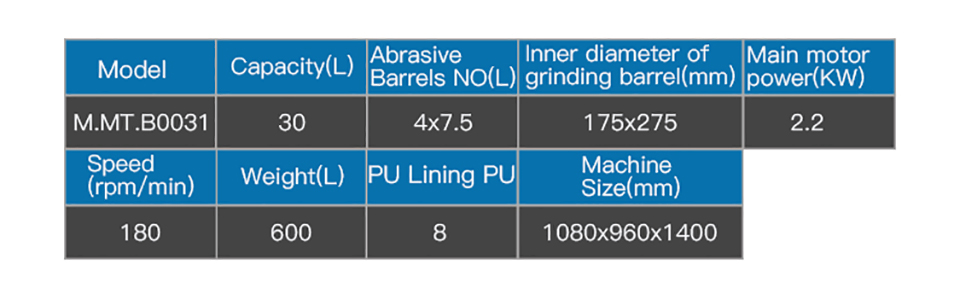

5. Efficient Design: The machine consists of four built-in satellite barrels mounted on a main rotary table. These barrels rotate at speeds ranging from 30 to 180 rpm, driven by a powerful motor. The main rotary table rotates clockwise, while the satellite barrels revolve counterclockwise, creating a strong centrifugal force that enhances the grinding effect.

Operation Principle:

The machine’s planetary rotation mechanism ensures thorough and even polishing. As the main rotary table turns, the satellite barrels create a counterclockwise revolution without rotating on their own axes. This movement generates a powerful avalanche effect within the barrels, where the media and workpieces experience intense friction and grinding, resulting in a smooth and polished finish.

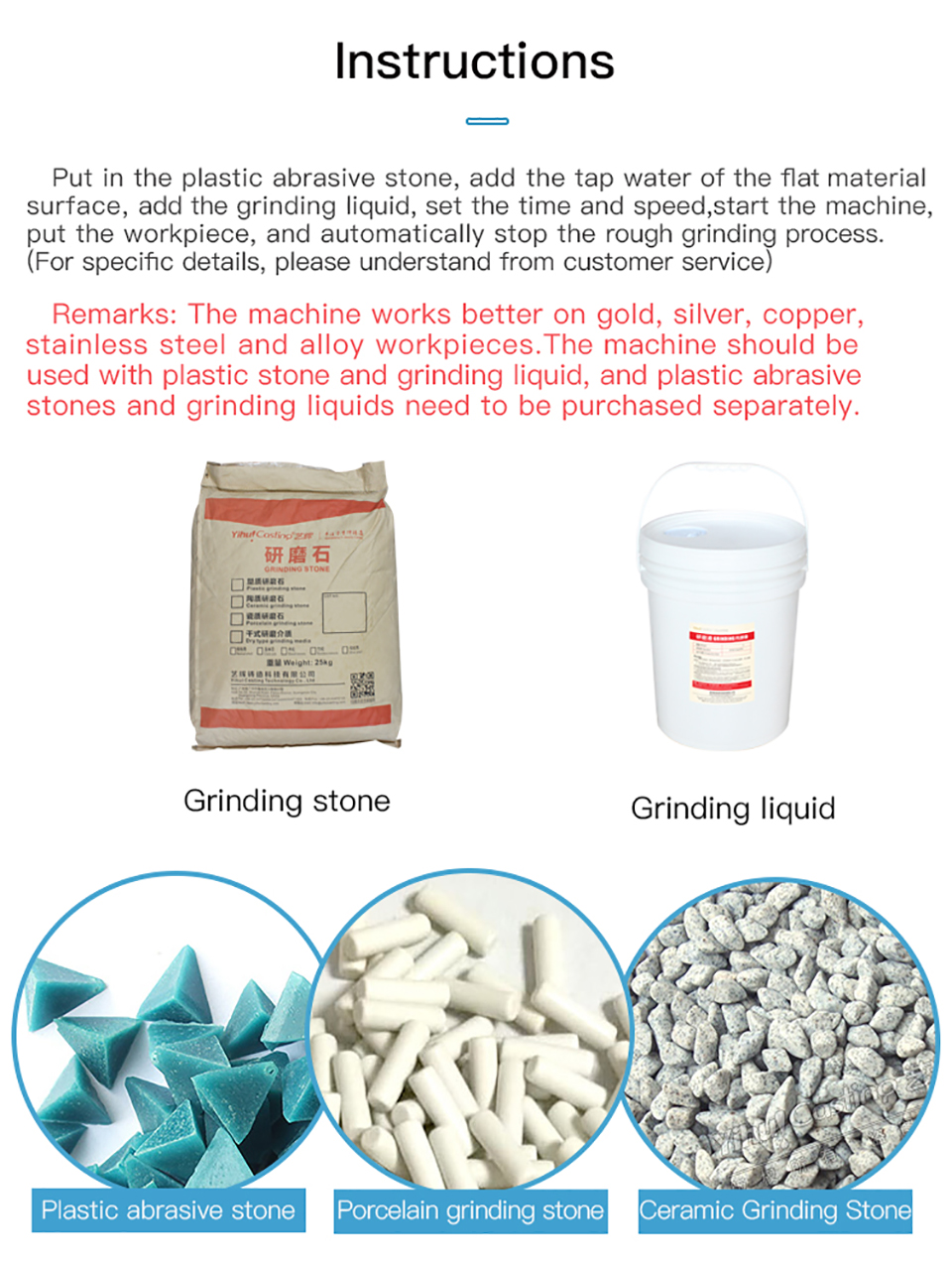

Operational Instructions:

To operate the machine, simply load the plastic abrasive stones, add tap water to cover the material surface, and introduce the grinding liquid. Set the desired time and speed, then start the machine. The process is fully automated, and the machine will stop once the rough grinding is complete. The machine is particularly effective on materials such as gold, silver, copper, stainless steel, and various alloys.

Important Notes:

- For best results, use the machine with plastic abrasive stones and grinding liquid, which need to be purchased separately.

- This machine is designed to handle a wide range of materials, making it a versatile addition to any manufacturing or polishing operation.

online service

online serviceScan to wechat :