Polishing tumbler for wet and dry polishing applications, featuring frequency conversion control, forward and reverse operation, and multi-specification options. Designed for precision hardware polishing and automation.

The Polishing Tumbler Series offers an innovative and efficient solution for polishing and finishing tasks across a variety of industries. With four versatile models to choose from—WF-36 Dry Type 36L (Single), WE-18 Wet Type 18L (Single), WS-18 Wet Type 18L (Double), and WS-18 Wet Type 18L (Triple)—these machines cater to a wide range of applications, including jewelry, precision hardware, watches, glasses, and non-metal components like jade and plastic.

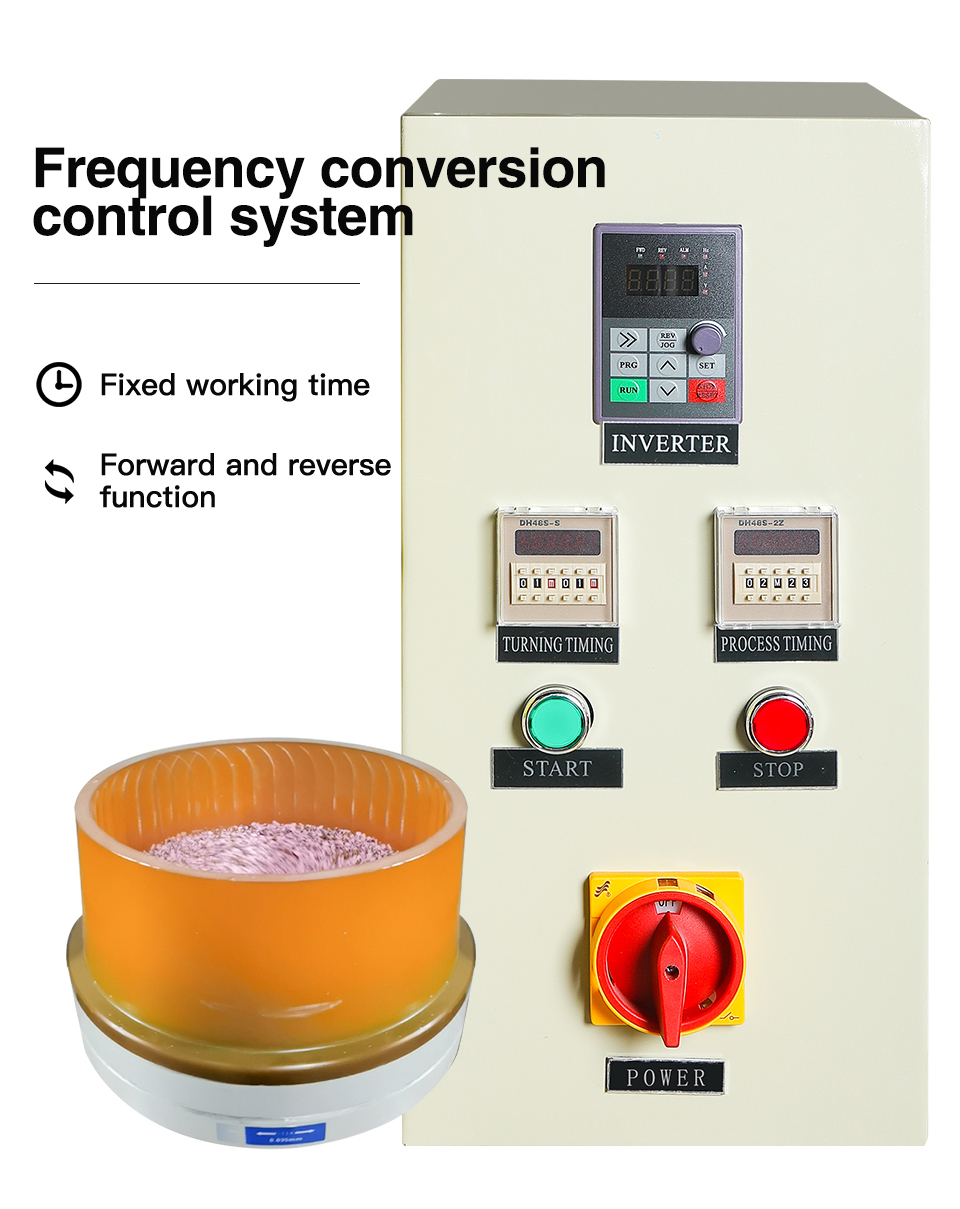

Each model in this series is equipped with advanced features such as frequency conversion control systems that ensure stable and precise operation. These tumblers are designed to handle both dry and wet polishing processes, making them adaptable to diverse requirements. Whether you need to polish gold, silver, or delicate non-metal items, these machines deliver smooth, uniform results efficiently.

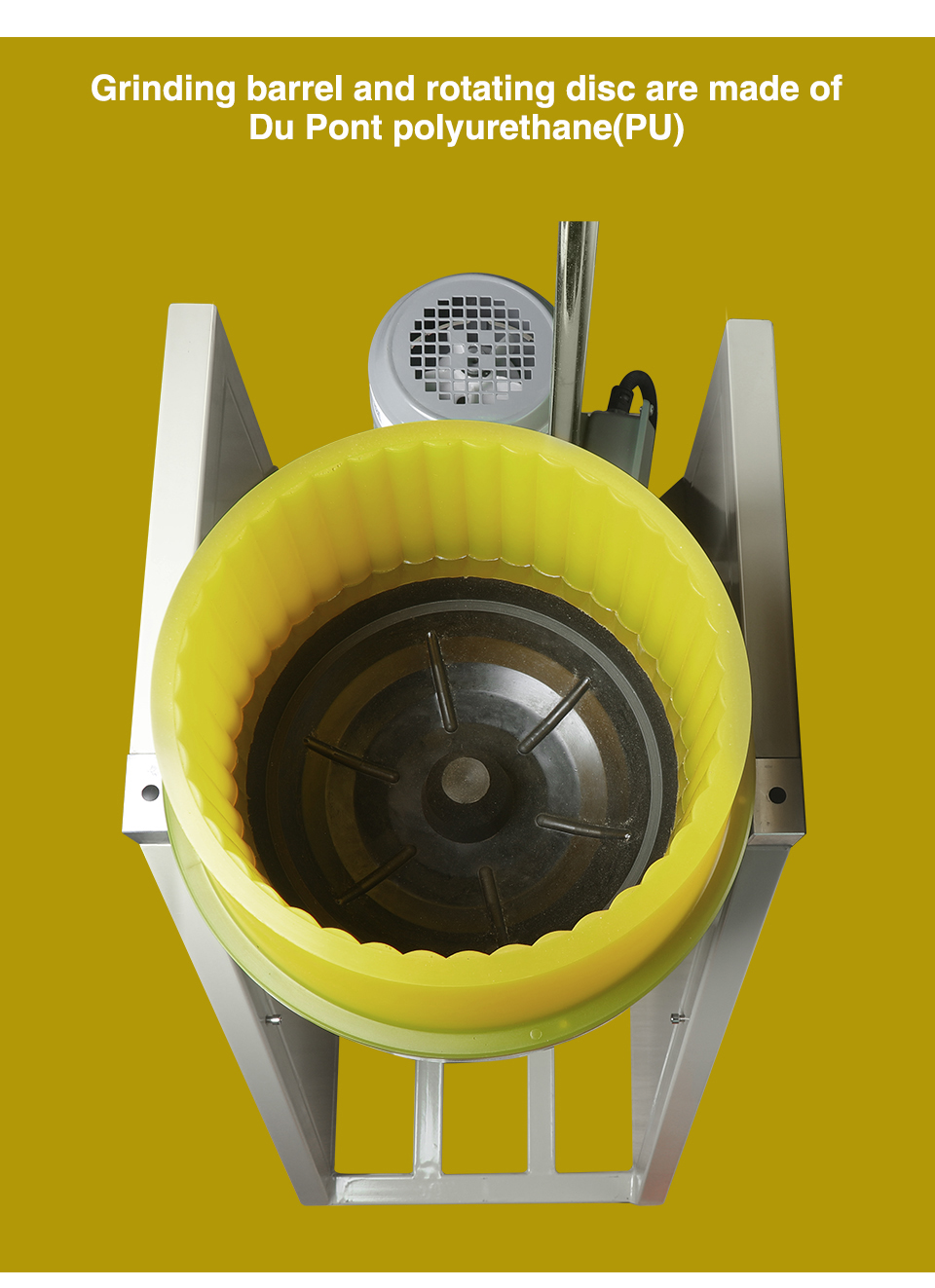

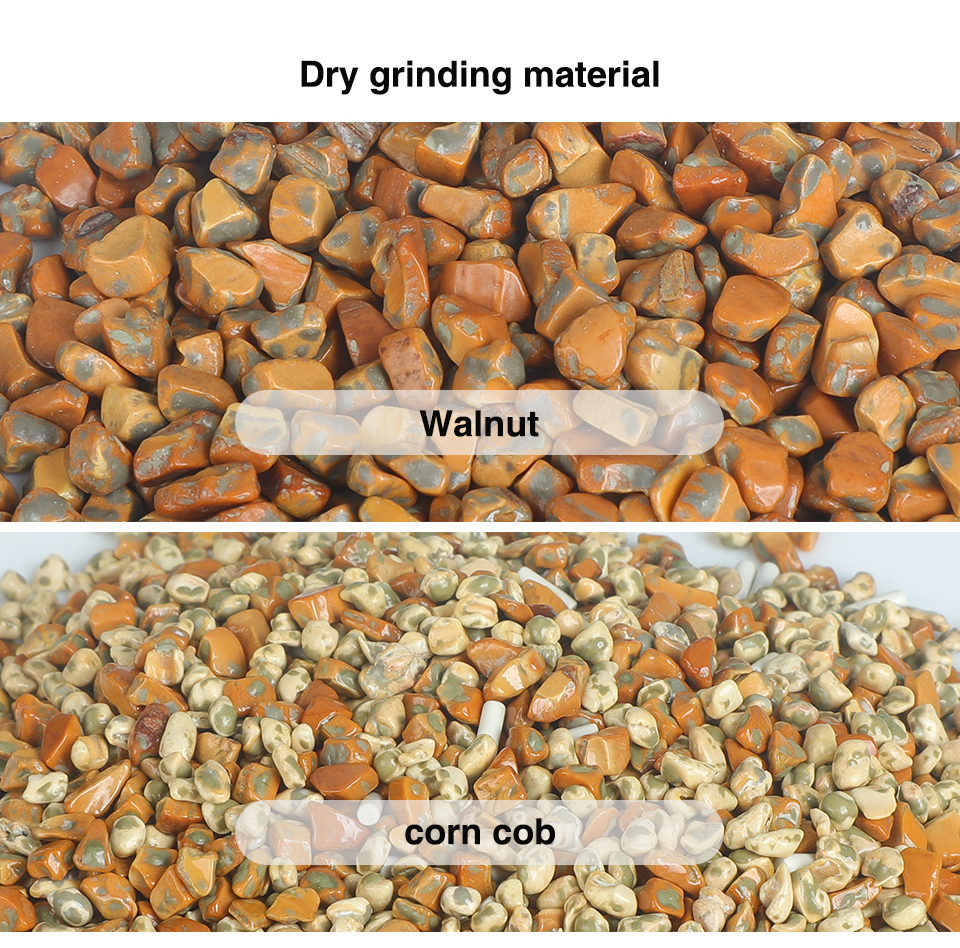

The dry polishing system in the WF-36 model utilizes specialized dry abrasive materials to remove burrs, chamfer edges, and achieve a fine surface finish. On the other hand, the wet polishing systems in the WE-18 and WS-18 models are designed for use with wet abrasive materials like plastic and porcelain, ensuring a polished and brightened surface for both metal and non-metal parts.

Adjustable Timing: The fixed working time function allows users to set precise polishing durations, ensuring consistent results with minimal supervision.

Forward and Reverse Functionality: This feature enhances polishing quality by providing uniform surface treatment and improving the efficiency of the grinding process.

Automatic Water Cycle System: In the wet models, the automatic cycle water system ensures continuous cooling and optimal operation, preventing overheating and extending machine life.

Multi-Barrel Options: The WS-18 models, available in double and triple barrel configurations, provide the ability to process multiple batches simultaneously, boosting productivity without sacrificing quality.

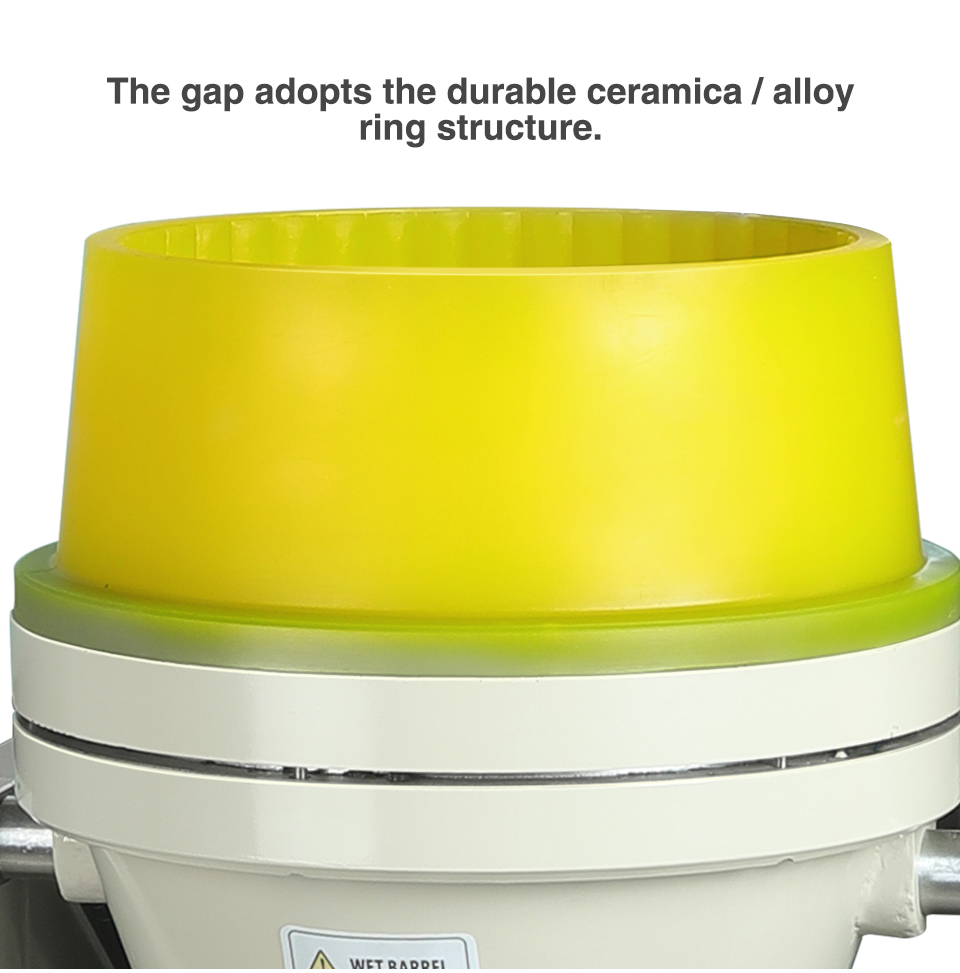

These tumblers are built with durable acrylic barrels, known for their wear-resistant and anti-corrosion properties. The high-power motor ensures reliable performance, while the machines’ compact and efficient designs make them easy to operate and maintain.

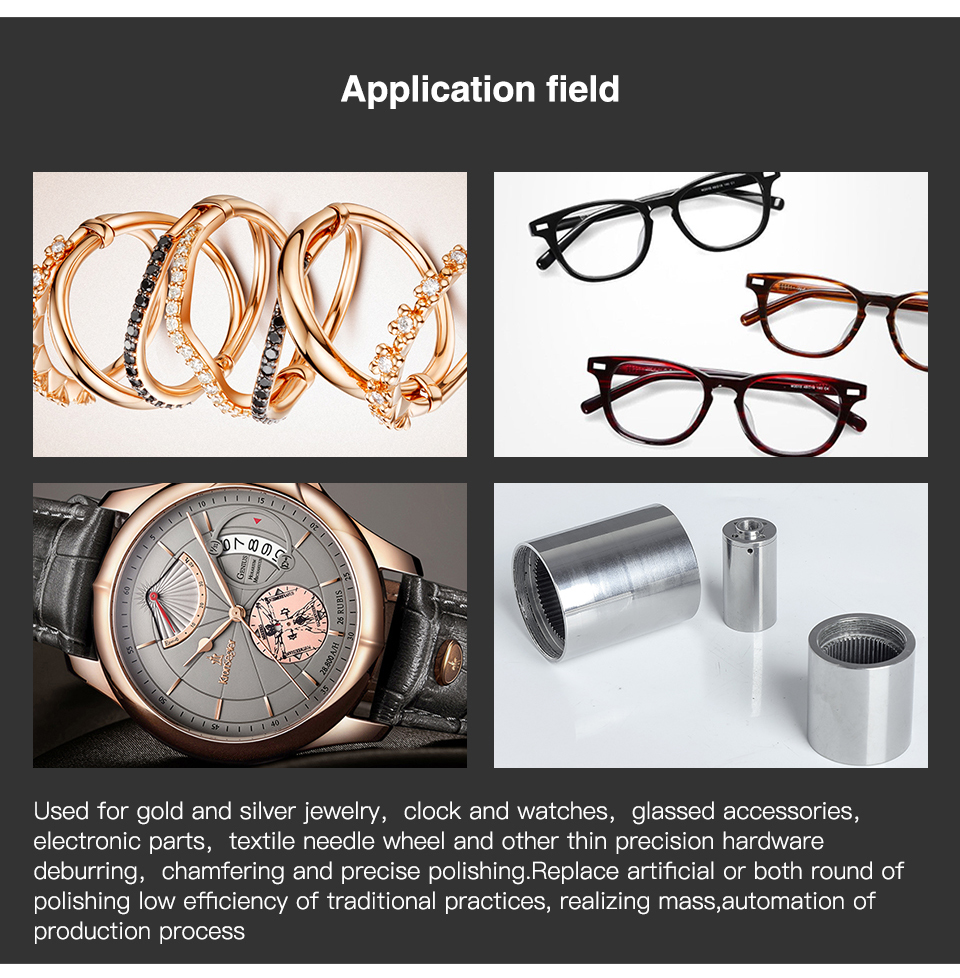

The Polishing Tumbler Series is widely used in industries such as:

Jewelry and Craftsmanship: Polishing and finishing gold, silver, and other precious metals.

Precision Hardware: Deburring and smoothing small components.

Watch and Glass Accessories: Achieving fine finishes on delicate parts.

Non-Metal Items: Perfect for polishing jade, plastic, and other softer materials.

By replacing traditional manual polishing methods, these tumblers offer a cost-effective, time-saving, and automated solution for high-volume production. The versatility of materials and configurations allows for customization to fit specific production needs, making them ideal for manufacturers looking to enhance efficiency and precision in their processes.

Frequency conversion control for stable performance

Adjustable timing for consistent results

Automatic cycle water system in wet models

Forward and reverse polishing options

Durable and wear-resistant acrylic barrels

Multiple barrel configurations for increased capacity

Whether you are handling small-scale polishing tasks or large-scale production, the Polishing Tumbler Series provides a reliable, efficient, and high-quality solution for all your polishing needs.

online service

online serviceScan to wechat :