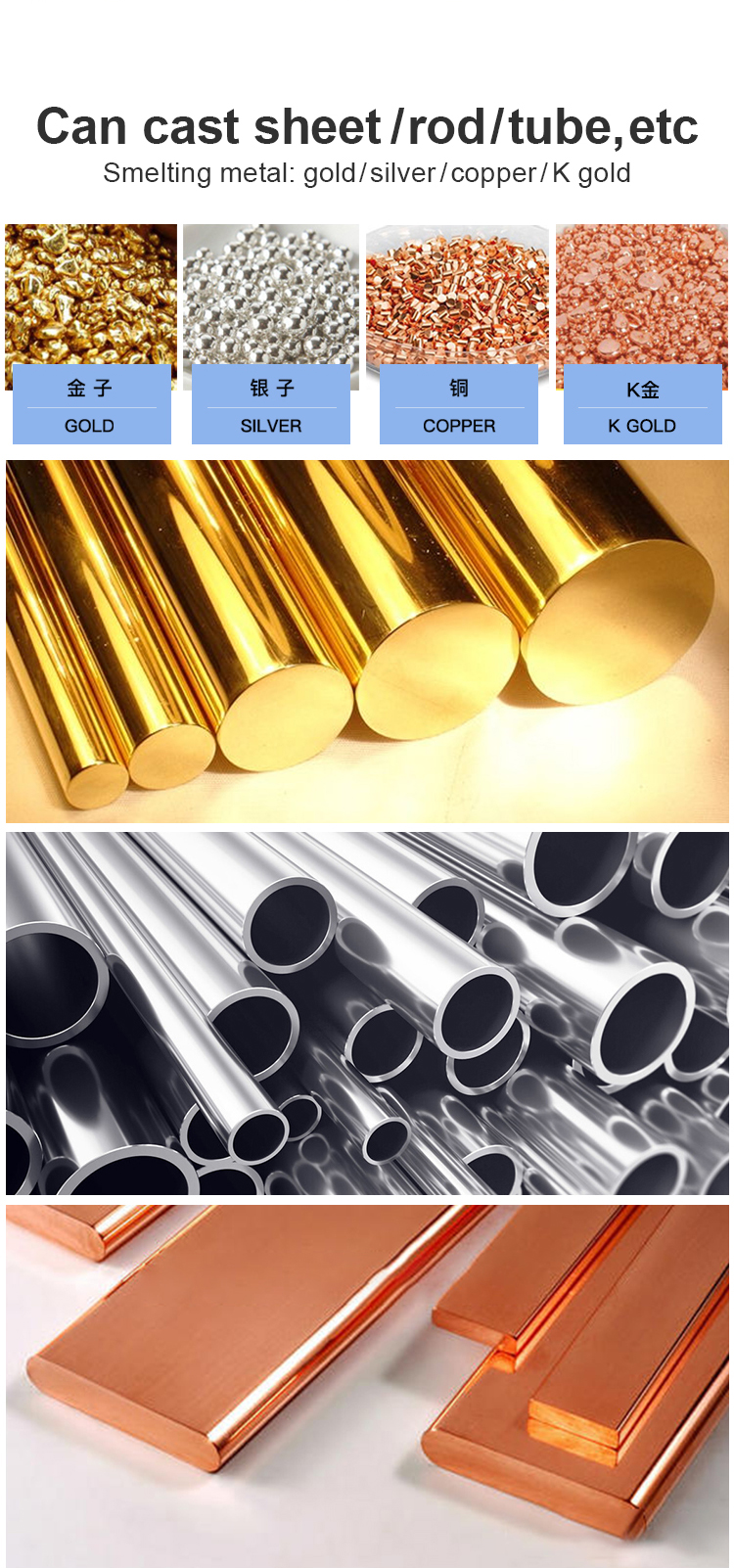

Introducing the ultimate Continuous Casting Machine, designed for maximum efficiency and unmatched performance. Ideal for crafting premium-quality precious metals, this machine incorporates advanced technology to elevate your casting game.

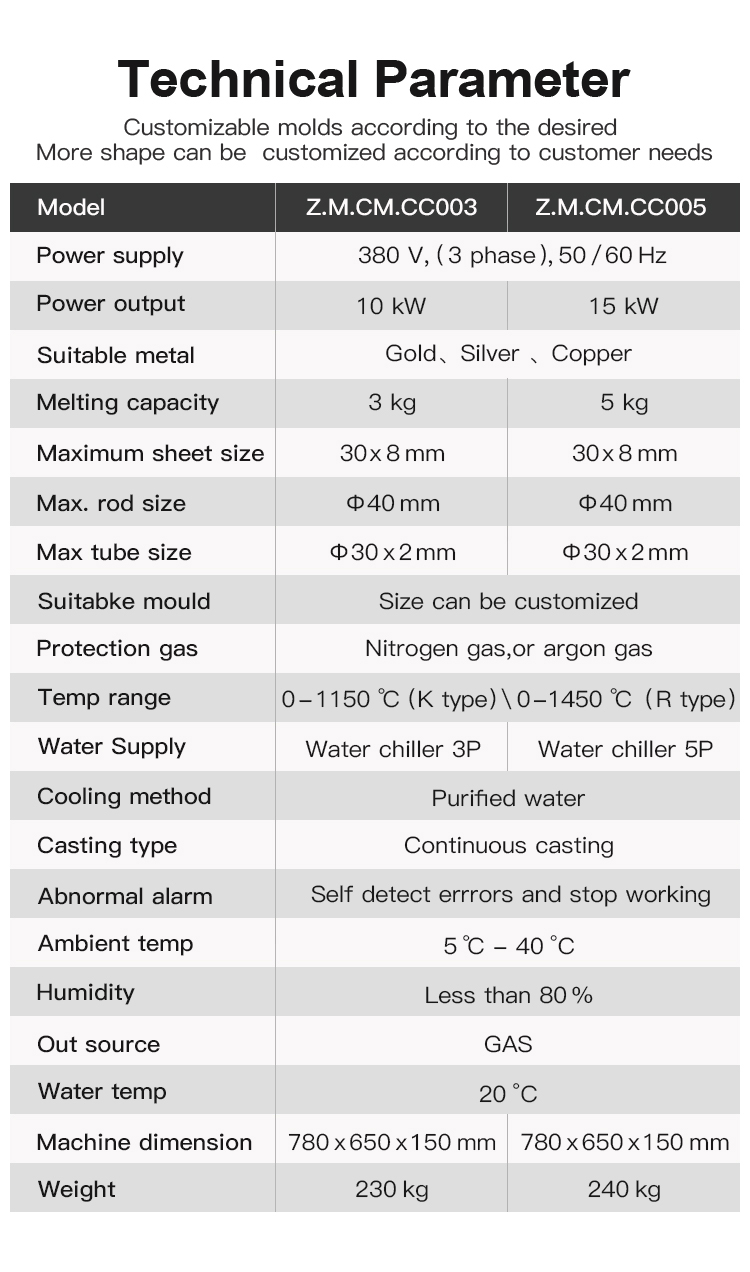

| Model | Z.M.CM.CC003 |

| Power supply | 380V, 3phase, 50/60HZ |

| Power output | 10KW |

| Suitable metal | Gold, Sliver, Copper |

| Melting capacity | 3KG |

| Maximum sheet size | 30×8mm |

| Max. rod size | Φ40mm |

| Max tube size | Φ30×2mm |

| Suitable mould | Size can be customized |

| Protection gas | Nitrogen gas, or argon gas |

| Temp range | 0~1150°C (K type) / 0~1450°C (R type) |

| Water Supply | Water chiller 3P |

| Cooling method | Purified water |

| Casting type | Continuous casting |

| Abnormal alarm | Self detect errors and stop working |

| Ambient temp | 5°C~40°C |

| Humidity | Less than 80% |

| Out source | GAS |

| Water temp | 10°C~20°C |

| Machine dimension | 780×650×150mm |

| Weight | 230KG |

Key Features:

1. Gas-Protected Melting: Ensures your precious metals remain free from oxidation during the melting process,

preserving their purity and integrity.

2. Dynamic Traction Casting: Enables swift and precise casting of various shapes including plates, round bars,

square bars, and intricate designs, all with minimal waste.

3. Minimized Sand Holes: The innovative down-draw casting method minimizes internal sand holes,

resulting in flawless finished products.

4. Stirring Induction Heating: Enhances metal dissolution uniformity, speeding up casting cycles and

accommodating larger cast volumes for deeper processing needs.

5. Omron Temperature Control (Imported from Japan): Precision temperature control ensures consistent

results and optimal metal quality.

6. Safety Self-Inspection System: Ensures machine safety and reliability with comprehensive self-diagnostics,

protecting your investment and production flow.

online service

online serviceScan to wechat :